The construction industry, often dominated by large-scale projects, frequently overlooks the potential of Lean methodologies in smaller businesses. Yet, a significant portion of construction work—estimated at 6.5 million workers in the US alone—is performed by small to medium-sized enterprises. This article presents a case study of how the Last Planner System (LPS) was successfully implemented within a 20-person HVAC company, debunking the misconception that Lean is only effective for large projects.

The Challenge: Adapting Lean for High-Volume, Short-Duration Work

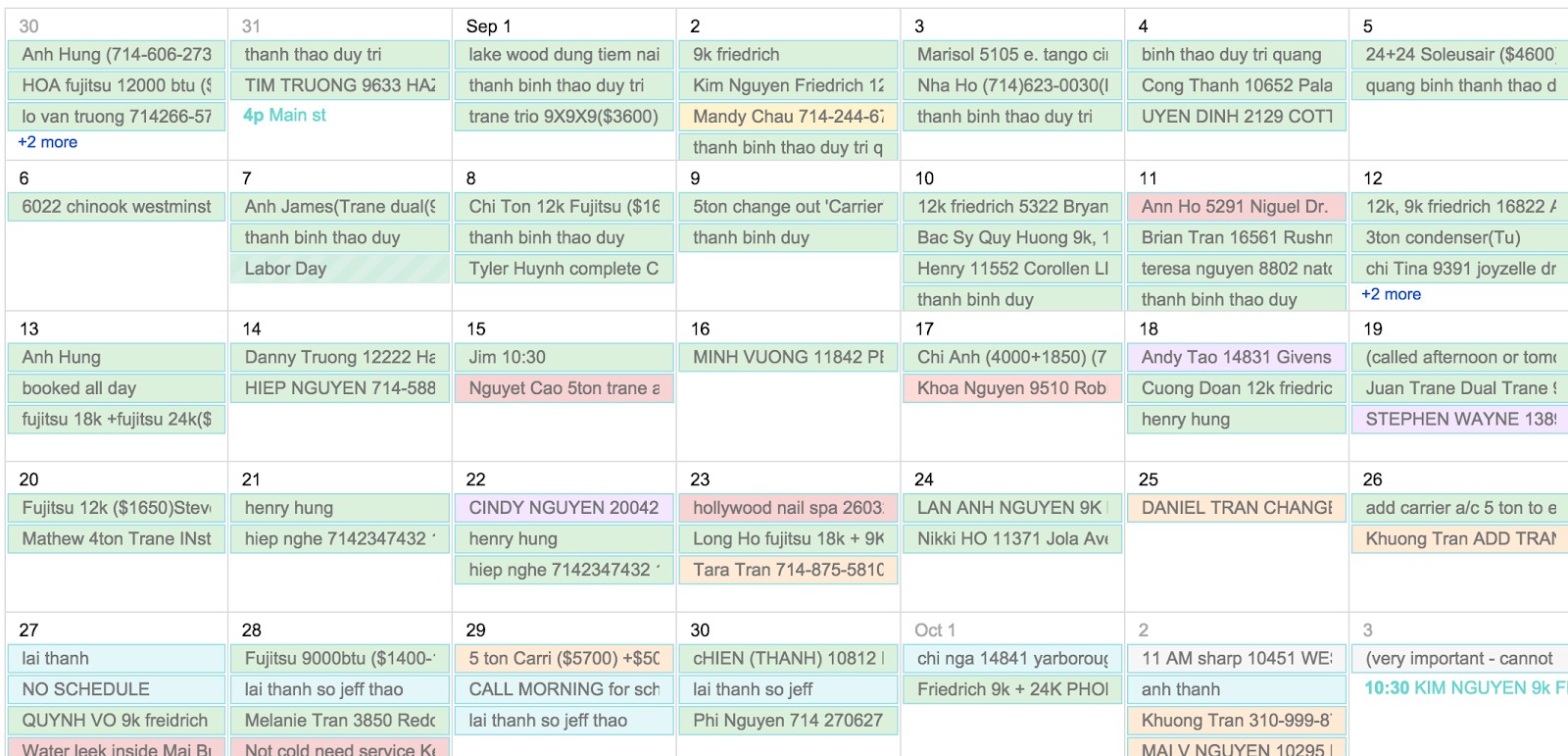

The D Air Conditioning Company, a full-service HVAC contractor in Orange County, California, handles approximately 500 residential installation projects annually. These projects range from full central air replacements to ductless mini-split installations and service calls. Unlike typical HVAC companies, D Air Conditioning maintains retail stores that serve as warehouses, enabling rapid material access. The key challenge was adapting LPS—designed for longer projects—to a high-throughput, fast-paced environment.

Implementing the Weekly Work Plan

The company’s production calendar—the central “schedule”—is managed weekly. Each entry includes the customer’s name, address, phone number, and the specific work order. Entries are color-coded to indicate readiness:

- Green: Materials and equipment are pre-staged.

- Purple: Service calls requiring no additional equipment.

- Orange: Projects requiring supplier coordination.

- Red: Breakdowns for analysis and future improvement.

This color-coding system ensures that materials are available before installation begins, minimizing delays. All breakdowns are documented to identify systemic issues and prevent recurrence.

The Make-Ready Process: A Pull System for Efficiency

A critical component is the “make-ready” process: ensuring the right equipment, materials, crew, and instructions are in place before the workday begins. Common materials are replenished using a pull system, ensuring availability without overstocking. At the end of each day, office staff stage materials and equipment for the next day’s projects, including customer invoices and instructions. Field crews collect these materials in the morning, streamlining the job-site setup.

Fostering a Learning Culture: The Role of Social Interaction

The company uniquely invests in its field crews by providing free breakfast and lunch. This isn’t merely a perk; it’s a deliberate strategy to foster a learning culture. Crews arrive at the store at 8 AM, load materials, and then gather for breakfast at a local restaurant between 9 AM and 10 AM. During this time, they discuss past projects, identify areas for improvement, and brainstorm solutions to recurring problems. This social interaction reinforces continuous learning.

Results: Increased Profitability and Satisfaction

Implementing Lean wasn’t without challenges—training, standardization, and cultural shifts were required. However, the results speak for themselves: net profit margins increased by 10%, customer satisfaction improved, and employee morale rose. This case study demonstrates that Lean isn’t limited to large-scale construction; it can be a powerful tool for small businesses seeking to optimize efficiency, reduce waste, and foster a culture of continuous improvement.

The key takeaway is that adapting Lean methodologies to specific business contexts—even high-volume, short-duration work—can yield substantial benefits. The Last Planner System, when properly implemented, is a versatile tool that can drive significant improvements in productivity, profitability, and employee satisfaction